Table of Contents

Graphene Coating V2.0

★★★★★ "Mind=Blown!! It is SO easy to apply! The gloss is insane and the hydrophobic properties are unbelievable." -Michael B.

Learn MoreCeramic Coatings hit the market with a ton of buzz and speculation in the early 2010’s and rapidly grew in popularity. At first ceramic coatings were almost exclusively used by professional detailers but as technology advanced DIYers soon began to adopt these coatings. Today Ceramic coatings have made their way into almost every facet of detailing and have solidified themselves as a proven detailing technology.

But hold onto your hats because there is a new kid on the block! In the summer of 2020, Graphene coatings blasted their way into the detailing industry with a large amount of buzz and speculation. We were the first company to release a consumer available, Graphene Coating in May of 2020 and soon realized there were quite a few questions and comparisons to answer.

The question on everyone's mind is, Which is Better? Graphene or Ceramic Coating?

So let's get into it.

What are Ceramic Coatings?

Ceramic coatings were designed to be a semi-permanent wax replacement technology to provide UV and environmental protection to automotive surfaces. These coatings when installed would cross link and covalently bond to paint surfaces, sealing them on a molecular level and creating a hydrophobic barrier between the vehicle and the environment.

These coatings are primarily made from variations of Silicon, Silicon Dioxide or other forms of Silicates. (Sio2) This ingredient provides a superior form of protection to that of normal carnauba waxes or polymer based sealants in its ability to resist weathering or degradation.

This was a huge step change in the industry and opened the doors for both detailers and enthusiasts alike to substantially improve their detailing regimen.

What is a Graphene Coating?

A graphene coating is an evolution of ceramic coating technology. Utilizing the latest graphene based technology to make a stronger, more durable coating that is easier to apply. In addition since Graphene is a less reactive ingredient it has been shown that Graphene based coatings are less prone to water spotting or etching compared to ceramic based chemistries.

There is still speculation that many products that are marketed today are simply ceramic coatings with graphene powder added, as mentioned in this video. But that couldn't be further from the truth.

Ethos Graphene Matrix for example, utilizes a Silazane backbone to bond Graphene atoms on a molecular level. This is simply the glue that bonds it to the surface, adding graphene powder to a ceramic coating would not add any benefit. To learn more about how our graphene coating technology works, checkout our blog: How Graphene Coatings Are Made.

It's technically a "hybrid" coating because it needs to be formulated with other elements to make it usable as a coating you can put on your car! You can expect your Graphene Matrix Coating to last up to 5 years! Compared to Ceramic Coatings, Graphene Matrix performs extremely well in many areas, such as water spot resistance, ability to reject water on contact, and surface hardness.

What is Graphene?

Graphene is graphite (Carbon) that has been processed to construct a one atom thick layer. This one atom thick layer is made up of carbon atoms arranged in a honeycomb lattice pattern that forms a nearly transparent sheet with some incredible properties. At a molecular level, it is 200 times stronger than steel, yet six times lighter and flexible.

How does graphene differ from conventional ceramic coatings?

There are quite a bit of similarities with ceramic coatings. For example, graphene also uses nanotechnology to bond to your vehicle’s paint thus ensuring molecular level sealing and protection. Yet what makes Graphene Coating a game changer? Ceramic coatings and graphene coatings both protect against UV rays, water, dirt, and some contaminants, but graphene has the advantage of being the strongest material on Earth! While also being one of the thinnest materials due to its one atom structure. Thinner yet stronger, is that possible!? YES!

Graphene Coating V2.0

★★★★★ "Mind=Blown!! It is SO easy to apply! The gloss is insane and the hydrophobic properties are unbelievable." -Michael B.

Learn MoreAre graphene coatings worth it?

Yes, Graphene is a wonder material that the car care industry finally has access to. The physical properties allow this coating to outperform any other coatings on the market. Being extremely easy to apply and maintain, Graphene Matrix is extremely cost-effective and gives you the most value out of any other coating.

Some additional benefits of Graphene Coatings Include:

- High water contact angle (more beading)

- Anti-static = Car stays cleaner longer

- Highly flexible (less susceptible to cracking or chipping)

- Ease of application

- Unsurpassed durability (5-10 years!)

The slickness factor of graphene is extremely high making it comparable to some of the best coatings and sealants on the market. If you’re a fan of that water beading effect then you’ll love graphene.

Some of the relative advantages over ceramic coatings are:

- Less prone to water spotting

- Easier application process

- Reduction in heat absorption on treated surfaces

- Longer durability

How much do Graphene or Ceramic Coatings cost?

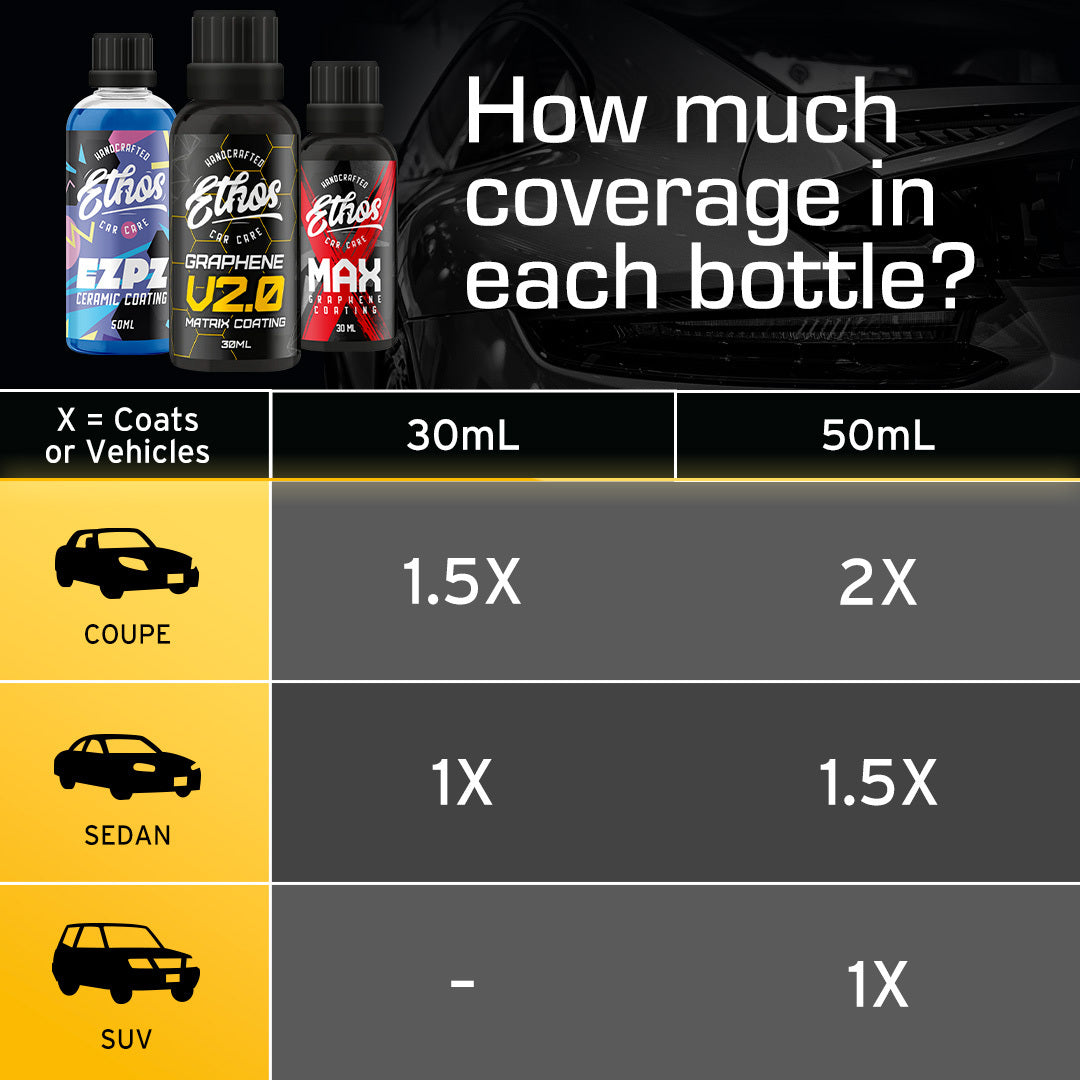

Pricing for these coatings can range depending upon the brand and volume of coating you purchase. On average expect to pay between $70 and $100 for 30ml of Graphene Coating (Enough to do a mid sized vehicle).

Ceramic coatings are slightly less expensive and range from $50-90 for 30ml.

How to Apply Graphene Coating Products

-

Apply a few drops of Graphene Matrix onto your applicator until evenly covered.

-

Starting with horizontal / top surfaces first, applying in straight lines slightly overlapping from one line to the next. Work in small areas approximately 3'x3' or the size of a door or half a hood at a time. Temperature and humidity will determine coverage areas allowable between application and removal.

-

Applicators should glide smoothly on the surface while laying down an even layer of coating. If the applicator starts to drag or the application becomes inconsistent, apply additional drops to the applicator.

-

Immediately after application, you will notice a “Rainbow Effect” (More prevalent on dark colors) while the applied coating bonds to the surface. Roughly 1-3 min after application, the "Rainbowing" will start to turn into a haze/fog, this means the coating is ready for removal. (Temperature and humidity will expedite the flash time. Test a small area first before continuing onto the rest of the vehicle)

-

Using premium microfiber towels (Preferably our Utility Towels), thoroughly wipe down the section to remove the Graphene Coating residue. Your first wipe should remove about 80% of the residue, and your second wipe should easily remove the remainder. Use small, circular motions and little to no pressure during removal.

-

Repeat these steps as you move along the rest of your vehicle. Coating the paint, plastics, trim and glass surfaces in the same manner. When layering the coating, one hour minimum is required between coats.

-

Let the coating fully dry/cure for at least 48 hours before allowing it to get wet. The longer it stays dry the better, as it will continue to cure for about 5 days (you CAN drive the car during this time).

Graphene vs. Ceramic Coatings: Which is Better?

There are a few reasons Graphene Coatings are better:

- Graphene Matrix utilizes this innovative technology to make a formula that takes ceramic coatings to the next level.

- Due to their graphene chemistry, these coatings can be easier to apply while providing additional benefits and results.

- With Graphene Matrix you should expect an incredibly high performing coating that is on the upper 99 percentile of gloss, with extremely high durability and incredible hydrophobic functions relating to very, very easy maintenance and cleaning.

- Increased resistance to water spotting, etching and other forms of damage that can be caused by the environment.

To Wrap It Up

Most ceramic coatings on the market are comprised of Sio2 (Silicone Dioxide) which is commonly referred to as Silica. Graphene was discovered in 2004 and won a nobel prize in 2010 due to its incredible attributes which have shown to be 100X stronger than steel while remaining flexible and not breaking. Utilizing graphene in an car protective coating has shown some incredible results!

5 comments

roger winter

Can you recomend a proffessional “shop” near zip code 33024? Pembroke pines, fl. Near ft. lauderale.

Thank you

Can you recomend a proffessional “shop” near zip code 33024? Pembroke pines, fl. Near ft. lauderale.

Thank you

Michael Croxton

Is there a recommended minimum time before applying graphene protection to a new base coat/clear coat paint job? Clear coat is Matrix, applied in 4 coats, over 4 coats of base, 2 coats of sealer, 6 coats of DIrect-to-Metal primer and a base series of one coat of Ospho, followed by two coats of an acid-etch primer.

Is there a recommended minimum time before applying graphene protection to a new base coat/clear coat paint job? Clear coat is Matrix, applied in 4 coats, over 4 coats of base, 2 coats of sealer, 6 coats of DIrect-to-Metal primer and a base series of one coat of Ospho, followed by two coats of an acid-etch primer.

JR Colon

Can I use Ethos Cleanse – Graphene Car Shampoo Graphene Ceramic Coating Infused Car Wash Soap in a car already with the ceramic coating?

Can I use Ethos Cleanse – Graphene Car Shampoo Graphene Ceramic Coating Infused Car Wash Soap in a car already with the ceramic coating?

Jeff

My question is how safe are these coatings and graphene ?do u wear a mask or body armor suit?does it cause cancer?what are the safety concerns thanks

My question is how safe are these coatings and graphene ?do u wear a mask or body armor suit?does it cause cancer?what are the safety concerns thanks

Cindy

Hi

I’m trying to apply graphene/ceramic coating on a granite sink for hydrophobic and scratch resistant properties. The sink is matte black so I’d prefer to avoid excessive sheen.

1) Which can best withstand the wear, temp fluctuations, scratch/chipping potential of a high-use kitchen environment?

2) How often do I reapply? Recommended maintenance?

3) Which of your product is best for this use case with minimal sheen?

Please provide me with a product recc, application & maintenance instructions. Thank you!

Cindy

Hi

I’m trying to apply graphene/ceramic coating on a granite sink for hydrophobic and scratch resistant properties. The sink is matte black so I’d prefer to avoid excessive sheen.

1) Which can best withstand the wear, temp fluctuations, scratch/chipping potential of a high-use kitchen environment?

2) How often do I reapply? Recommended maintenance?

3) Which of your product is best for this use case with minimal sheen?

Please provide me with a product recc, application & maintenance instructions. Thank you!

Cindy